MAESTRO rescue descenders: when facing the unexpected

On big walls, in ravines, or in confined spaces, the new MAESTRO descenders always provide the right solution for efficient rescue operations.

Compact and lightweight (1100g), they offer unparalleled versatility : whether raising and lowering heavy loads, or when serving as the main or backup belay system. The ergonomic handle, integrated brake, AUTO-LOCK system, and integrated progress-capture pulley mean that rescuers can adapt to any situation they may face during a rescue.

What are the differences between each version?

Both the MAESTRO S and MAESTRO L have the same design and features. The differences between each model are rope diameter compatibility (10.5 mm to 11.5 mm for the MAESTRO S, and 12.5 mm to 13 mm for the MAESTRO L) and maximum load (250 kg for the MAESTRO S and 280 kg for the MAESTRO L).

MAESTRO features

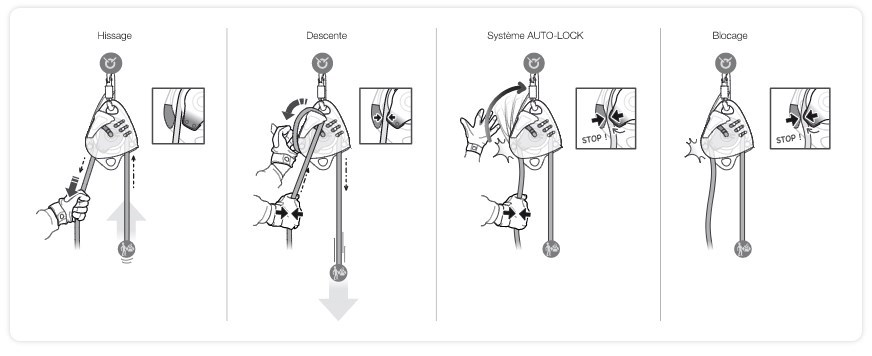

The MAESTRO combines the abilities of a progress-capture pulley and a descender for effective hauling, releasing and lowering of the load. The AUTO-LOCK system locks the load automatically and returns the handle to the stop position.

WARNINGS

- Read the technical notice before viewing the following techniques.

- It is important to fully understand the information provided in the technical notice before using this complementary information

- Mastering these techniques requires training.

- Consult a professional before attempting to perform these techniques on your own.

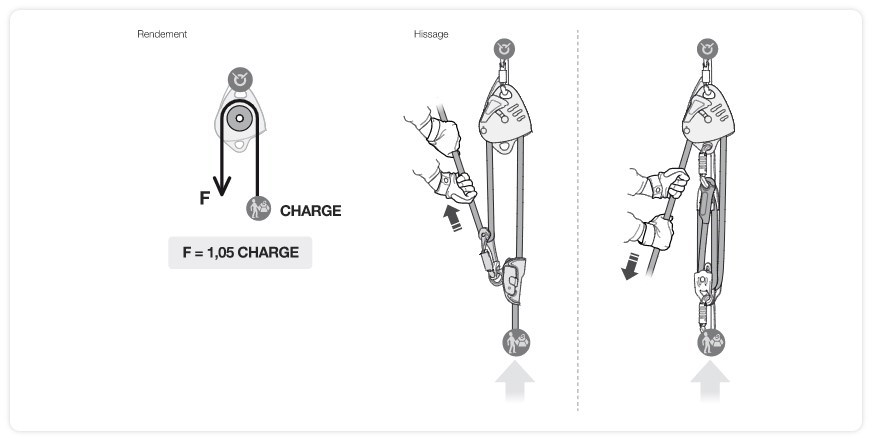

1. Working principle

The MAESTRO uses a pulley mounted on a ratcheting wheel, which allows the rope to run in one direction and lock in the other direction. In the rotation direction the pulley enables rapid rope glide.

In the other direction, the rope locks by being pinched between the moving brake plate and the fixed brake plate.

- The rope can run in the hauling direction, even when the moving brake plate is in the lock position: hauling is always possible, even when the rope is locked, without having to operate the handle.

- The handle enables the lock to be released so that the rope can run. The brake-side rope must be held when operating the handle, to ensure proper control of the descent.

- The AUTO-LOCK system locks the load automatically and returns the handle to the stop position

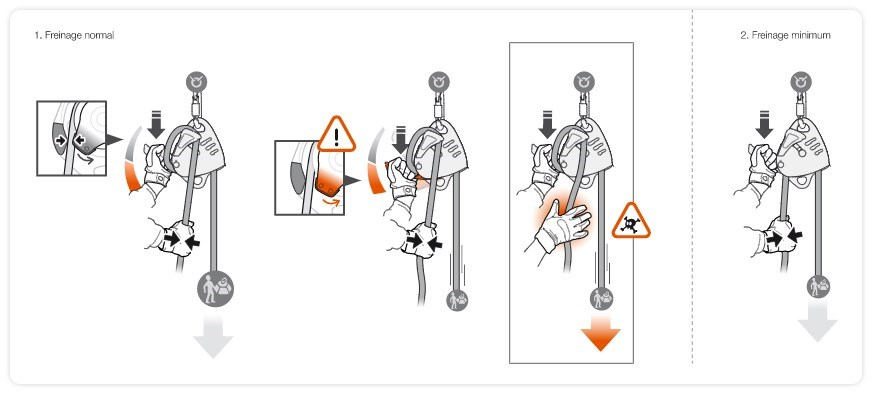

2. Varying friction to control the descent

Normal friction: every descent must begin with the rope running over the external brake.

Direct the rope so that it always stays in place inside the brake. Beware of twists or loops of rope that could cause the rope to come out of the brake.

Minimum friction: during the descent, if there is too much friction, (swollen or dirty rope, light load...), the rope can be removed from the external brake.

In all cases, the brake-side rope must be held during the descent.

WARNING: the movement of the handle releases the lock; the more the handle is pulled, the more the moving brake plate disengages to let the rope run. If the handle is pulled too far, the moving brake plate will no longer brake the rope.

Warning: any excessive pulling on the handle can cause a loss of control.

3. Hauling efficiency

The large diameter sheave mounted on ball bearings offers great efficiency at the head of a haul system or in a counterbalance situation.

The lock is released automatically when the rope runs in the hauling direction, with no need for any specific manipulation by the user.

For setting up complex pulley systems, the MAESTRO has an auxiliary attachment hole.