REQUEST FOR INSPECTION OF PETZL LOW-STRETCH KERNMANTLE ROPES

One of our clients found 2 critical defects on his Petzl low-stretch kernmantle ropes. To date, no other client has reported similar defects to us, and no accident or injury is known. Please read the information below and, if necessary, inspect your ropes.

Request for inspection of Petzl low-stretch kernmantle ropes:

- AXIS 11 mm

- ASAP'AXIS 11 mm

- PARALLEL 10.5 mm

- VECTOR 12.5 mm

- RAY 12 mm

- SEGMENT 8 mm

- CLUB 200 10 mm

- PUSH 200 9 mm

- TOP 9.8 mm

- LEAD 9.8 mm

- KIT including these ropes

With serial numbers between 18 C 0000000 000 and 20 H 0000000 000

While unpacking new Petzl AXIS 11 mm ropes, one of our customers found the following two defects:

- a deep cut in an AXIS 11 mm rope manufactured in June 2019

- a 2.1-meter scrap of rope taped to one end of an AXIS 11 mm rope manufactured in September 2019

To date, no other client has reported similar defects to us, and no accident or injury is known.

Our in-depth investigation and risk analysis have led us to the following conclusions:

- the two defects occurred on one of our rope-cutting machines

- the two defects have common root causes

- the risk of the two defects occurring is near zero (only a complex sequence of multiple, independent factors could lead to the occurrence of the defects)

- this risk did not exist prior to March 2018

- only the ropes cut on this machine are at risk of these defects

We took immediate corrective actions to eliminate this risk on the production line. Our stock is in the process of being inspected and no further defect has yet been found.

As a precaution, we ask that you immediately inspect each of your low-stretch kernmantel ropes listed below that have a serial number between 18 C 0000000 000 and 20 H 0000000 000:

- AXIS 11 mm

- ASAP'AXIS 11 mm

- PARALLEL 10.5 mm

- VECTOR 12.5 mm

- RAY 12 mm

- SEGMENT 8 mm

- CLUB 200 10 mm

- PUSH 200 9 mm

- TOP 9.8 mm

- LEAD 9.8 mm

- KIT including these ropes

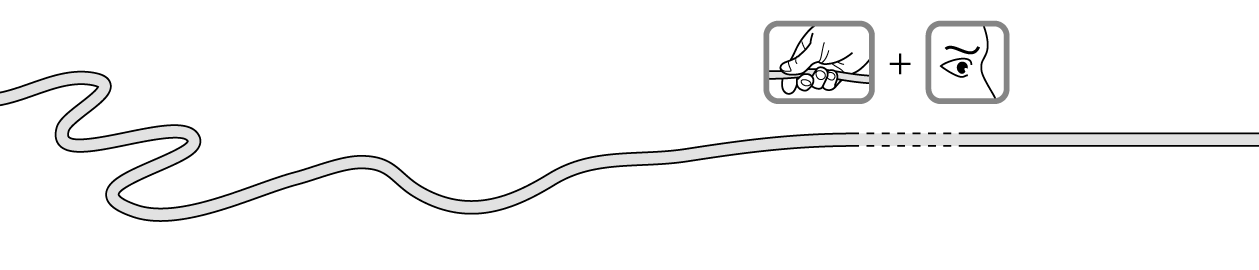

The inspection must be carried out by hand, without gloves, along the entire length of the rope, and in accordance with this operating procedure.

If you find any defect, please quarantine your rope immediately and contact us.

The inspection we are asking you to carry out fulfills certain criteria from the detailed periodic inspections you must carry out at least once every 12 months. However, if you encounter any difficulty carrying out the inspection, please contact us.

We are aware of the inconvenience that this inspection request may cause; please accept our apologies. Our customers’ safety remains our top priority, and all of our teams are making every effort to assist you

We thank you in advance for your understanding and are relying on you to immediately report to us any defect found.

Inspection operating procedure

In order to carry out the low-stretch kernmantle rope inspection, we ask that you follow these operating procedures:

- Is your low-stretch kernmantle rope on the list of Petzl ropes affected by this inspection request?

- NO → your rope is not affected by the inspection request

- YES → go to paragraph 2

- I don't know → as a precaution, go to paragraph 2.

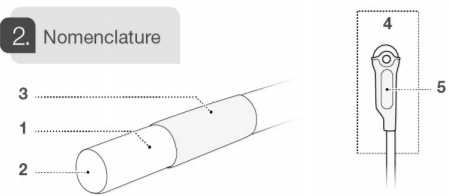

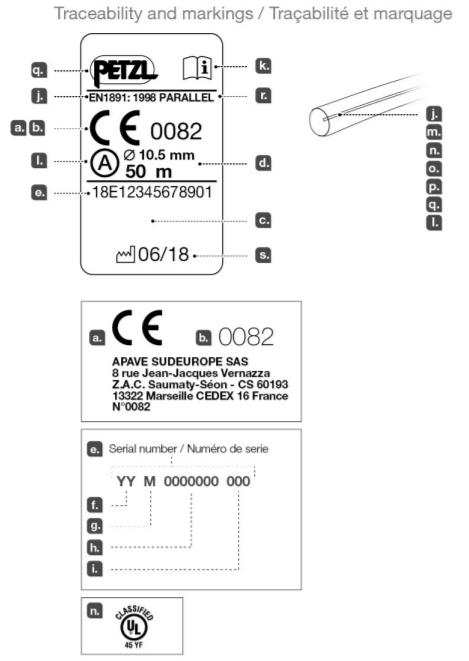

- Identifying the serial number on your rope:

Your rope’s serial number is on the label affixed to each end of the rope, on its Instructions for Use, and on your PPE register.

Example of a serial number: 18 C 01254697 807

- My rope’s serial number is: YY M xxxxxxx xxx → go to paragraph 3

- I can’t find my rope’s serial number → go to paragraph 4

- Is your low-stretch kernmantle rope’s serial number between 18 C 0000000 000 and 20 H 0000000 000?

- YES, the first three characters of the serial number are: 18C, 18D, 18E, 18F, 18G, 18H, 18I, 18J, 18K, 18L, 19A, 19B, 19C, 19D, 19E, 19F, 19G, 19H, 19I, 19J, 19K, 19L, 20A, 20B, 20C, 20D, 20E, 20F, 20G

→ your rope is affected by the inspection request → go to paragraph 4

- NO (example: 18 B 9999999 999) → your rope is not affected by the inspection request

- Is your rope new and never-used?

- NO (it has already been used) → go to paragraph 5

- YES → go to paragraph 6

- Has your rope already been used or inspected in one of the following ways?

- installation of the rope by running your hand along its entire length without gloves

- coiling the entire length of the rope without gloves

- detailed periodic inspection of the rope already carried out

NO, or I’m not sure → go to paragraph 7

YES → you do not need to inspect your rope again, and we ask that you inform us on the registering my rope inspection form

- Is there a green sticker on the box of my new rope?

- NO → it has not already been inspected → go to paragraph 7

- YES → your rope has already been inspected by a professional and you do not need to inspect it again

- Inspecting your rope by hand, without gloves, along its entire length:

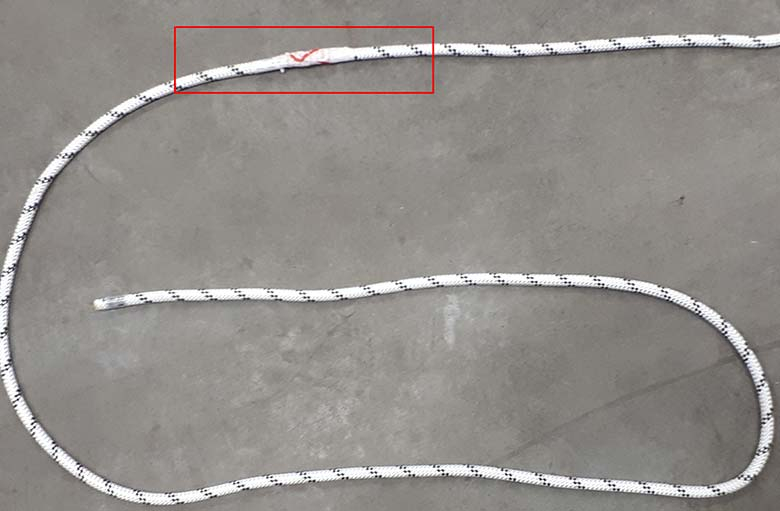

Only production defects (1) and (2) below are affected by this inspection request. If you find a defect described in this inspection request, please write down the serial number of the affected rope, immediately quarantine the rope and contact us.

(1) Production defect covered by this inspection request (2) Production defect covered by this inspection request

As a reminder, if during the course of this inspection you find a defect caused by wear or anomalies covered by PPE inspection sheet criteria, retire your rope

Two examples of rope usage wear => Retire the product

- Once your rope has been inspected, we ask that you enter the result on the registering my rope inspection form.

- If you run into problems or difficulties carrying out the rope inspection, please contact us.

FAQ

1 - When and how did you find out about the problem?

While unpacking new Petzl AXIS 11 mm ropes, one of our customers found the following two defects:

- a deep cut in an AXIS 11 mm rope manufactured in June 2019

- a 2.1-meter scrap of rope taped to one end of an AXIS 11 mm rope manufactured in September 2019

2 - Have any accidents involving a defective rope occurred?

To date, no other client has reported similar defects to us, and no accidents have been reported to us.

3 - How do you explain the problem?

Our in-depth investigation and risk analysis have led us to the following conclusions:

- Both defects occurred on one of our rope-cutting machines

- Only the machine we purchased and started operating in March of 2018 is affected by the risk of such a defect occurring

- The risks of these two defects occurring have common root causes (human/machine interface)

- The risk of the two defects occurring is near zero (only a complex sequence of nine independent factors could lead to the occurrence of either defect).

4 - Why aren’t ropes manufactured before March 2018 affected?

In March 2018, we purchased and started using a new standard type of machine used in the rope measuring and cutting sector. It was on this new standard machine that we detected the risk of a defect occurring through a complex sequence of nine independent human-machine interface factors.

5 - What is the probability that my rope has one of the defects?

The risk of the two defects occurring is near zero (only a complex sequence of nine human/machine independent factors could lead to the occurrence of either defect). The defect is very unlikely to occur with the machine, but the seriousness of potential bodily harm is such that a rigorous inspection of each potentially affected rope is mandatory.

Corrective actions to eliminate the risk were immediately undertaken, and our stock is currently being inspected. To date, no other defect has been found.

6 - Why were these two defects not detected earlier?

The occurrence of the two defects occurring is extremely unlikely and near zero, since only a complex sequence of nine independent human/machine factors could lead to the occurrence of either defect.

7 - Do I absolutely have to inspect my rope?

Yes, unless you fall under an exception identified in our operating procedures.

8 - If I already inspected my ropes when I first started using them or during my periodic PPE inspection, do I have to inspect them again?

If you already inspected your rope when you first used it, or during periodic PPE inspection, you would already have found any defect covered by the inspection request. You do not have to inspect it again for the inspection request.

9 - If I don’t have any PPE inspection training, can I perform the inspection?

Any adult of able mind and body who knows how to use a rope can perform the inspection. The operating procedures will walk you through each step of the inspection.

10 - I don’t know how to inspect my rope or I’m not sure what to do.

Read the operating procedure.

11 - How do I inspect my rope?

Because the defect is so easily detectable to the touch, the inspection must be carried out by hand, without gloves, along the entire length of the rope, and in accordance with the operating procedures.

12 - Is my low-stretch kernmantle rope affected by the inspection request?

Low-stretch kernmantle ropes manufactured after March 2018 with a serial number between 18 C 0000000 000 and 20 H 0000000 000 and that appear on the list below are covered by the request.

Affected ropes:

- AXIS 11 mm

- ASAP’AXIS 11 mm

- PARALLEL 10.5 mm

- VECTOR 12.5 mm

- RAY 12 mm

- SEGMENT 8 mm

- CLUB 200 10 mm

- PUSH 200 9 mm

- TOP 9.8 mm

- LEAD 9.8 mm (dynamic rope)

- Kits that include these ropes

Note: ropes manufactured before March 2018 are not covered by this inspection request.

13 - Is my dynamic rope affected by the inspection request?

No, dynamic ropes are not covered by the inspection request because they are cut to length on a different rope-cutting machine that does not present a risk of such defects occurring.

The LEAD 9.8 mm rope is the only dynamic rope affected by the inspection request, because it was cut to length on the only rope-cutting machine that does present a risk of the defects occurring.

Note: this LEAD 9.8 mm rope is intended solely for climbing gym operators.

14 - If my rope is part of a kit, should I inspect the whole kit?

No, the inspection request only covers the rope in your kit. However, you may use the opportunity to inspect the entire kit. As a reminder, you must carry out a detailed periodic inspection of your PPE (personal protective equipment) at least once every 12 months.

15 - Is the JAG SYSTEM rope covered by the inspection request?

No, the JAG SYSTEM rope is not covered by the inspection request because it is cut to length on a different rope-cutting machine that does not present a risk of such defects occurring. However, the AXIS rope from the JAG RESCUE KIT is covered by the inspection request.

16 - How do I find my rope’s serial number?

All of our products have an individual name and number to identify them.

The name and serial number are on the label affixed to each end of the rope.

If you no longer have the serial number, we ask that you carry out the inspection as a precaution. You can find more information in the Technical Notice that came with your rope and which are available at Petzl.com.

17 - I want to buy a new low-stretch kernmantle rope. How can you guarantee that the ropes available in stores are compliant?

Since the defect was discovered, Petzl has corrected its low-stretch kernmantle rope-cutting machine, inspected all of its stock, and asked all of its dealers to inspect their stock and relay the call for inspection to their own clients.

Our dealer clients are committed and knowledgeable professionals who will inspect their own inventory. However, we cannot guarantee that, in accordance with our request, all of the dealers’ rope inventory will have been inspected by the time of your purchase.

This is why, as a precaution, we strongly advise that you follow the inspection operating procedures before using your new rope.

18 - I found a little green sticker on my rope packaging. What does it mean?

All ropes manufactured between March 2018 and July 2020 that have already been inspected by Petzl or other professionals are required to have a green sticker on the rope packaging.

Because the manufacturing machine has been secured, we will stop placing green stickers on packaging of ropes manufactured as of August 1, 2020 (serial number > 20H xxxx).

19 - What do I do if I find a manufacturing defect?

If your rope has a manufacturing defect, we ask that you quarantine your rope immediately.

20 - If I am currently in a country where there is no distributor, who should I contact?

21 - Is the rope from my GRILLON lanyard covered by the inspection request?

No, the GRILLON rope is not covered by the inspection request because it is cut to length on a different rope-cutting machine that does not present a risk of such defects occurring.

22 - Which kits are covered by the inspection?

All kits with a low-stretch kernmantle rope listed in the inspection request are covered by the inspection.

23 - Are my PUSH and CLUB ropes covered by the inspection request?

Only the PUSH 200 and CLUB 200 ropes with a length of 200 meters are covered by the inspection request. Shorter ropes are not affected, because they are cut to length on a different rope-cutting machine that does not present a risk of such defects occurring.