3M Cubitron II Fibre Disc 982C

The 3M Cubitron II Fibre Discs are engineered to cut faster, cooler and with less grinding pressure than conventional abrasives. And they are long-lasting for increased productivity! For mild steel applications.

3M™ Cubitron™ II Fibre Disc 982C offers optimum performance and productivity on carbon steel with our exceptionally high-performing 3M Precision Shaped Grain combined with a stiff fibre backing, and generates up to twice the cut-rate, durability, and life of other fibre discs—all with less grinding pressure.

Fiber discs are heavy-duty discs ideal for weld removal, grinding, and blending large and small areas of metal surfaces. They feature a tough, stiff backing made from vulcanized fiber that resist wear and can handle tough grinding applications.

- 3M Precision Shaped Grain maintains super-sharp points that cut exceptionally fast with less pressure

- Disc life is significantly longer, completing more parts per disc and requiring fewer disc changes

- Triangular-shaped ceramic grain wears evenly, runs cool, and optimises mineral breakdown

- Stiff fibre backing and a strong resin bond provide durability and tear-resistance for heavyweight applications such as high-pressure weld grinding, and can be used wet or dry

- 22mm centre hole mount is compatible with 3M™ Disc Pad Face Plates and Hubs, and requires the use of a disc retainer nut (all sold separately)

- Complete carbon steel solution

|

Attachment Type

|

Centre Hole

|

|

Backing Material

|

Fibre

|

|

Bonding Type

|

Resin

|

|

Brand

|

Cubitron™ II

|

|

Center Hole Diameter (Metric)

|

15.875 mm, 16 mm, 22 mm, 22.225 mm

|

|

Coat Type

|

Closed Coat

|

|

Grit

|

36+, 60+, 80+

|

|

Hole Configuration

|

394EQ, 453EQ, 492EQ, 709EQ

|

|

Industries

|

Marine, Metalworking

|

|

Max Speed

|

12000 rpm, 13200 rpm, 15000 rpm, 8500 rpm, 8600 rpm

|

|

Mineral Type

|

Precision Shaped Ceramic

|

|

Overall Diameter (Imperial)

|

3.937 in, 4 in, 4.5 in, 4.528 in, 4.921 in, 5 in, 7 in, 7.087 in

|

|

Overall Diameter (Metric)

|

100 mm, 101.6 mm, 114.3 mm, 115 mm, 125 mm, 127 mm, 177.8 mm, 180 mm

|

|

Product Form

|

Disc

|

|

Sub Industries

|

Metal Fabrication

|

| Model/Series | Cubitron II |

|---|---|

| 3M Order Code | 60440230021 |

| Brand | 3M |

| Country of Manufacture | |

| Application Category | Angle Grinders |

| Abrasive Application | Blending, Grinding, Light Grinding |

| Abrasive Performance | Best |

| Used on | Aluminium, Carbon Steel, Cast Iron, Nickel Alloy, Non-Ferrous Brass/Bronze, Stainless Steel, Titanium |

| Overall Diameter | 101.6mm |

| Form Type | Disc |

| Attachment Type | Centre Hole |

| Max RPM | 15000 |

| Mineral Type | Ceramic |

| Grit | 36+ |

| Coat Type | Closed Coat |

| Product Form | Disc |

With 3M Precision-Shaped Grain, the future is now. This technological breakthrough is the backbone of our industry-leading 3M™ Cubitron™ II Abrasives and Advanced Series 3M™ Silver discs, wheels and belts. The uniformly sized ceramic aluminum oxide triangles cut faster and last longer than traditional abrasives – giving you an edge over the competition.

Every "In Stock" order received is shipped with 12-24 hours. We're proud of our track record, which has seen 98% of deliveries to most metropolitan areas made in 1-2 working days. All Items up to 5Kg are shipped Express for a flat fee of $19.95

Metropolitan Area

Brisbane, Sydney, Melbourne, Perth

1-2 Business Days

Adelaide

2-3 Business Days

Regional Area

Queensland, New South Wales, ACT, Victoria, South Australia, Western Australia

2-3 Business Days

Northern Territory

5-6 Business Days

Tasmania

5-7 Business Days

Our standard freight charge is $19.95 so whether you order 1 item or multiple items, the flat fee is $19.95

Please note:

- Heavy Large & Dangerous goods will be calculated at the checkout.

- Please note: most signs are made-to-order. Please allow 5 to 7 business days for any custom orders.

Delivery T&Cs

- Most orders within Australia are delivered by Australia Post.

Delivery Costs

- Our prices depend on the total weight and size of your order unless advertised otherwise.

- To find the total cost of the order add the items you wish to purchase into the shopping cart, including your full delivery address the shipping costs will be automatically calculated and displayed on the checkout page.

Ship Large, Heavy or Dangerous Items

We reserve the right to substitute the shipping carrier you have selected at checkout if we have reasonable grounds to believe the carrier will be unable to render the services they have advertised at the agreed price. Should this occur we will provide you with the details of the substitute carrier and a revised quotation from another carrier. You will have the right to accept the revised quotation or to cancel the transaction without penalty.

Despatch

- Orders are despatched from various distribution centres around Australia.

- We proudly work with a highly streamlined despatch team, with most items being despatched within 1-2 business days upon confirmation of payment.

- All "in stock" items are despatched within 2-7 business days.

- All orders are processed in the order as received with Express Postage orders taking priority.

Signature on Delivery

-

All orders placed on our website are sent with Signature on Delivery this adds extra security to your parcel as delivery will only be made if someone is available to receive the parcel. If no one is available the parcel will be taken to a nearby Post Office for collection.

Authority to Leave

- If a Authority to Leave (ATL) is requested for your parcel to be left in a safe place, we take no responsibility in missing, lost or damage parcels based on this request.

Delivery Times

We have partnered with Australia Post, Toll and TNT. Australia's largest and most trusted courier companies to offer you prompt and safe shipping across Australia in most circumstances.

In most instances estimated delivery times from the time of despatch will be displayed at checkout, and are based on ALL products being "in stock" at the time of ordering:

Metropolitan Area

Brisbane, Sydney, Melbourne, Perth

1-2 Business Days

Adelaide

2-3 Business Days

Regional Area

Queensland, New South Wales, ACT, Victoria, South Australia, Western Australia

2-3 Business Days

Northern Territory

5-6 Business Days

Tasmania

5-7 Business Days

The above estimated delivery times are in business days (Monday through Friday) excluding public holidays.

Every effort is made to ship your order according to the estimated delivery times provided, estimated delivery times may change due to unforseen circumstances from the couriers.

Please allow at least ten (10) working days for delivery from receipt of your order and payment for your order. Delivery time is subject to stock availability, product size and location. Items marked "instock" are generally dispatched within 1-2 working days of purchase.

If your product has not arrived after the estimated delivery time, please contact us by email by REPLYING to your order confirmation email to support(at)worksafegear.com.au with a brief message.

Unless otherwise agreed to by us, we will deliver your products to the address indicated on your order confirmation. If no-one is available to recieve the delivery, the courier (TNT, DHL or Australia Post) will leave a card requesting you to arrange a suitable time and date for delivery or collect from their distribution centre.

Additional fees may apply for re-delivery of orders.

We will use reasonable efforts to deliver your item/s to you within the estimated delivery time indicated on your order confirmation; however, we are unable to guarantee that the delivery will be made within this time frame.

Upon despatch of your order you will receive a copy of your tracking information from the nominated courier.

In the event of express shipping being requested for an item(s) that is not "in stock", you will be contacted by a customer service representative.

We are able to deliver your items to your home, work or P.O. box address Australia wide, including all property addressed rural and remote areas of our great country. For larger items that need to be sent via courier, a street address is mandatory, and you will be notified during the checkout process.

International cost and other delivery costs

- In most cases, international shipments are delivered in a timely manner. However, it can take several weeks depending on your country's customs regulations.

- For all international orders we are not responsible for customs clearance or any duties or taxes that might be charged.

- All our international orders will be shipped by the best carrier (Australia Post, TNT, DHL, FedEx).

Transit Insurance Cover

- Peace of mind - If your goods happen to be lost or damaged while they're in AusPost Care, you won't be out of pocket.

- Fast, hassle-free claims - Improved process lets you track the status of your claim.

- Cover is available for parcels valued up to $2,000 only.

Express Delivery

- Your Item will be picked, packed and manifested within 12-24 hours of placing your order on business days.

- Depending on the time that you place your order, it will be in transit to you within 12-24 hours on business days.

- This service is only available for stocked items. Backordered items will be expressed shipped once they arrive into our warehouse.

- Only available for items 5 kilos and under.

Stock Definitions

In Stock

If a product is in stock, you can add it to cart and proceed to the checkout. Once your purchase has been successful, we will process your order and ship it according to our Delivery terms and conditions.

Below is an example of a product in stock

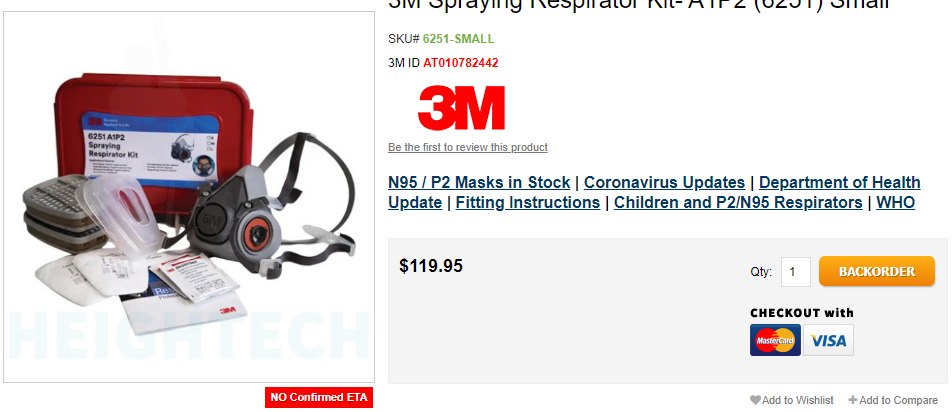

Backorders with approx. ETA and Backorders with no confirmed ETA

If a product is on Backorder with an approximate estimate time of arrival, you will be able to add it to cart as a Backorder and proceed to the checkout. Once your purchase has been successful, your order will be in the queue for dispatch when we have received the product in one of our warehouses. The ETA is the approximate date that our supplier has provided us and may change due unforeseen circumstances and if that's the case we will inform you with options. Your order will be shipped according to our Delivery terms and conditions.

Due to the Global Shortage for respiratory products we have no confirmed ETA’s.

COVID PPE, If you are not prepared to wait for your Backorder, DO NOT BACKORDER/PREORDER,

Should you cancel a backorder a $10+GST admin fee will apply.

All Backordered/Preordered COVID PPE, cannot be cancelled. This means NO Cancellation, NO Refunds and NO Change of Mind.

Our focus is to provide respiratory products to the frontline personnel and health care services during this unprecedented time.

COVID PPE , If you are not prepared to wait for your Backorder, DO NOT BACKORDER/PREORDER,

Should you cancel a backorder a $10+GST admin fee will apply.

Full T&Cs Quick Links