Hosted by the North America DROPS Chapter, this event was held at the Westin Houston. Over 100 industry leaders and representatives came together in an open and collaborative environment to share best practice in sustaining dropped object prevention improvements.

Opening Address

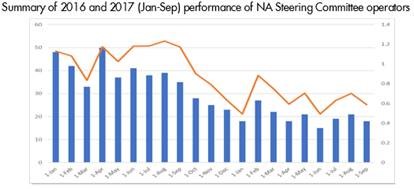

Following a welcome and safety briefing, Tyler Brown (North America DROPS Steering Committee) recognised the dedication, support and valuable input of the regional steering committee members. Providing an update on the current state of the industry in respect of dropped objects, the below graphic was shared as a baseline for an “industry average dropped object rate” (YTD Incidents/200k man hours). The data represents performance of the four operator members of the North America DROPS Steering Committee. It was mentioned how several dedicated efforts not only within the operators but also key contractors have been able to have a strong influence. The committee has put forth the Recommended Practice, now published by DROPS, with several operators pointing to it as a contractual baseline. Other work currently in progress includes a revision to the DROPS calculator and establishing a web based lessons learned portal, similar in scope to IADC but specific to dropped objects. A strong message through the opening and reiterated throughout the day was that safety is not and should not be proprietary, and open forums such as this one provide an opportunity to share and learn how best to protect our workforce from common exposures.

The 5 Fundamentals - Jordan Buss, Baker Hughes

The theme for the Forum was the 5 Fundamentals (of performance, of accident preventions, of a perfect HSE day); here it was introduced and discussed how Baker had adopted this “back to basics” approach. Each element (Identify Hazards, Control Risk, Follow Process and Procedures, Manage Change, Learn and Improve) was given examples about how it was implemented in the business with the mindset that HSE is not separate from Operational Excellence. What I found most intriguing is the retirement of separate HSE standards, instead incorporating their requirements into written Ops standards and procedures. Click here to view or download the presentation.

Learning & Improvement - Andre Dingee, ADE Group

Learning and Improvement was covered first, and Andrew chose to speak a lot about human behavior in this regard. Several case studies were presented both on how humans retain information and what is the most effective way of communicating (the debrief). He made comparisons to how aviation 30 years ago was in close to the same spot that O&G is now when it comes to effectively transferring intraorganizational learnings. The O&G current state is really built upon building knowledge of individuals through experience, but even when that experience is shared, often times it’s in an impersonal manner to which others cannot relate. Two challenges I took away here were to make our learnings personal and relatable, and to better standardize how learnings are incorporated into standard work. Click here to view or download the presentation.

Quality Control of 3rd Party Inspections - Al Browning, Rowan

Al spoke on the strategy that Rowan has incorporated to drive their dropped object management system. A critical element of this was identifying the hazards within the current state of their fleet, and while the company has made the decision to have an internal, DROPS focused audit team, 3rd parties were hired for immediate evaluation. Historically, what most 3rd party DROPS audits will provide is a list and pictures of everything that was not compliant, but Rowan took the time to cover their standards and expectations with the inspectors and work with them to get down to the root cause of deficiencies. This provides not only an actionable list, but an effective look at the implementation of the program from an outside perspective. Click here to view or download the presentation.

Finger Latch Enhancements - Ian McWilliam, NOV

Finger latches have long been commonly associated with dropped object exposure, but recently were also involved in a fatality in the GoM. At last years’ Forum, NOV was challenged as to how they are managing these recognized exposures in the design phase of equipment to provide functional fingers without the exposure. This year, Ian came in to share the work that has been done, including new circuit diagrams with positive feedback for the driller and new method of pneumatic functionality as well as temporary solutions in the form of visual confirmation through cameras. Click here to view or download the presentation.

Relevant NOV product bulletins and retrofit information is attached; further information can be found through your NOV rep or by emailing houstonservicedept@nov.com.

Recommended Practice Implementation - Bert Winders, Baker and Callum Wilkinson, Hess

Two committee members spoke about their organizations’ DROPS expectations from the perspective of both contractor and operator. Bert reiterated how Baker is gap assessing now against the Recommended Practice with standards and procedures that incorporate elements of dropped object management. Click here to view or download Bert's presentation. Callum spoke on the need for alignment and how differing operator requirements create a confusing environment for those companies that perform the majority of work. In that light, Hess is looking internally to the Recommended Practice to ensure that their standards not only meet industry minimum requirements, but also that there is no Hess-specific language that is communicated to contractors as mandatory. Click here to view or download Callum's presentation.

Management of Change in Nuclear - Douglas Ferguson, Lowther-Rolton

Doug was an investigator in the 2013 Arkansas Nuclear One event and regularly performs technical audits on engineering systems. The 2013 event was analyzed through one such technical audit and ended with an evaluation of lifting and hoisting operations and capabilities. The result was a change in rated lifting equipment. This event resulted in one fatality that is due in part to deviation from a plan. Despite the strength of the nuclear industry in procedural adherence, the change was not thought to be one that initiated an MOC process. This led to personnel under the impression that their position was within a protected area, but ended in the line of fire when the stator fell during change out operations. Click here to view or download the presentation.

Keynote Executive Panel Discussion

Participants:

Mike Clark, VP Ops, Rowan

Ron Fullerton, VP Offshore Ops, H&P

James McDonald, VP RCG Ops, Schlumberger

Tiffany Pitts, VP Offshore Ops, Baker Hughes

Mike Skuce, VP Ops US, Precision

There was a reiteration of the “Safety is not proprietary” message. From the drilling and service provider perspective, most opportunities to work toward an industry standard is a step in the right direction as it allows them to focus their HSE management systems without the customization required for operator specific requirements. By making safety and/or dropped object prevention a goal of operations management and staying engaged, these executives saw an opportunity to influence improvement all the way down the line. Emphasis was also placed on contractual requirements with equipment manufacturers to provide equipment that meets their and/or industry DROPS standards at the time of purchase, eliminating the need to retrofit or “make DROPS compliant.” This was a recognized opportunity during procurement. Finally, the point was raised that we need to have a better conversation with all the companies that will be interacting onsite and what interface will exist with dropped object management. While all participating companies exceed the minimum requirements, in some cases the details of standards may have some variance, or another, less mature contractor may be present. Though conversations are had during DWOP/CWOP, these normally do not go into those details despite this being a high risk area, leaving an opening to expand on the conversation during project planning.

Verification & Validation - Ingrid Punt, Raj Kunjappy, Chevron

Chevron has instituted a program called Verification & Validation as part of yet wholly separate from assurance. The process approach is conducted in four steps by identifying risks, knowing safeguards, understanding how safeguards can fail, and enhancing the verification process. Dropped Objects constitute some of the highest recognized risk in scope, Chevron spoke about different types of verifications are in place to manage risk and how the V&V not only manages the verifications, but validates that verifications are themselves withstanding as a barrier in an effort to better know that barriers are intact and functional. Click here to view or download the presentation.