Twin tail fall arrest lanyards (interim advice)

Purpose

To highlight the risk of failure when using twin tail fall arrest lanyards.

The guidance in this Alert is an interim measure and additional guidance will be provided as further information becomes available.

Background

A worker recently received fatal injuries as a result of falling from a transmission tower near Toowoomba. The worker was using a twin tail fall arrest lanyard at the time of the incident when he fell. He suffered fatal injuries when his lanyard failed.

Workplace Health and Safety Queensland (WHSQ) is currently investigating the incident and the exact causes of failure have not yet been determined.

Twin tail fall arrest lanyard

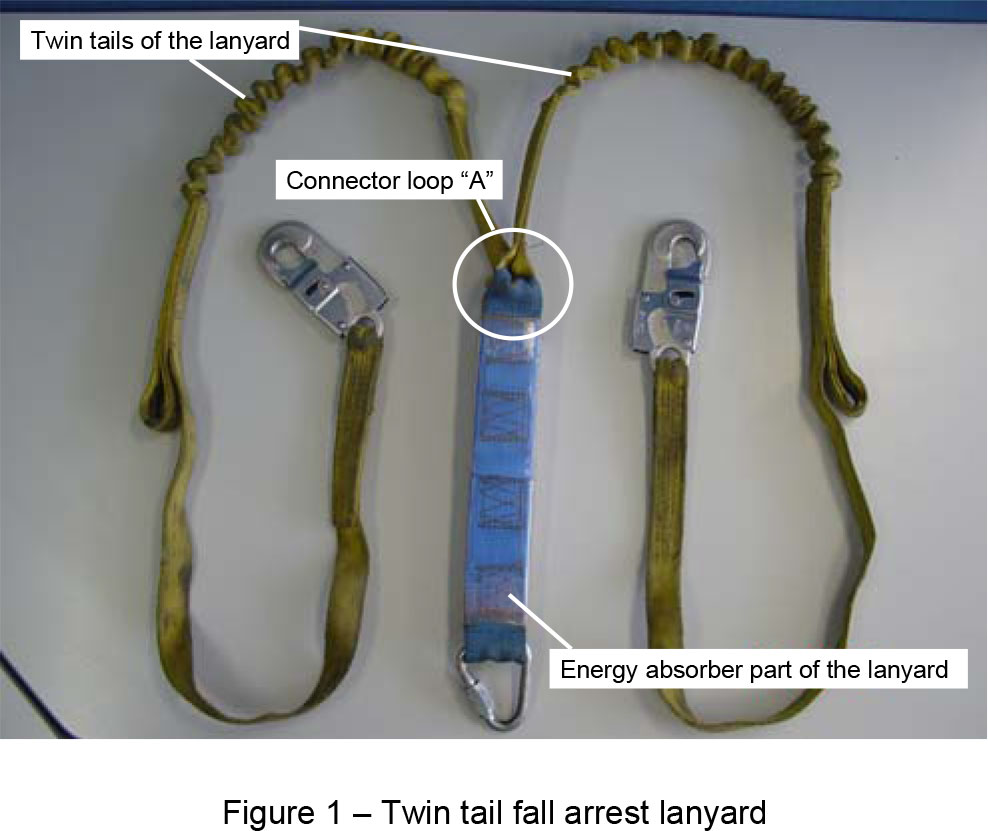

The twin tail arrest lanyard is the term used to describe a fall arrest system where a worker uses the twin tails of the lanyard to hook on and off as he or she climbs a structure. In this method the climber is always connected to the structure via one of the tails as he or she climbs the structure. An example of a twin tail type lanyard can be seen in Figure 1.

Results of preliminary investigations

In summary, tests conducted on similar types of lanyard revealed that:

- The energy absorber part of the lanyard operated as intended, when the twin tails were both connected to anchor points (on a structure) and the energy absorber part was connected to the body harness.

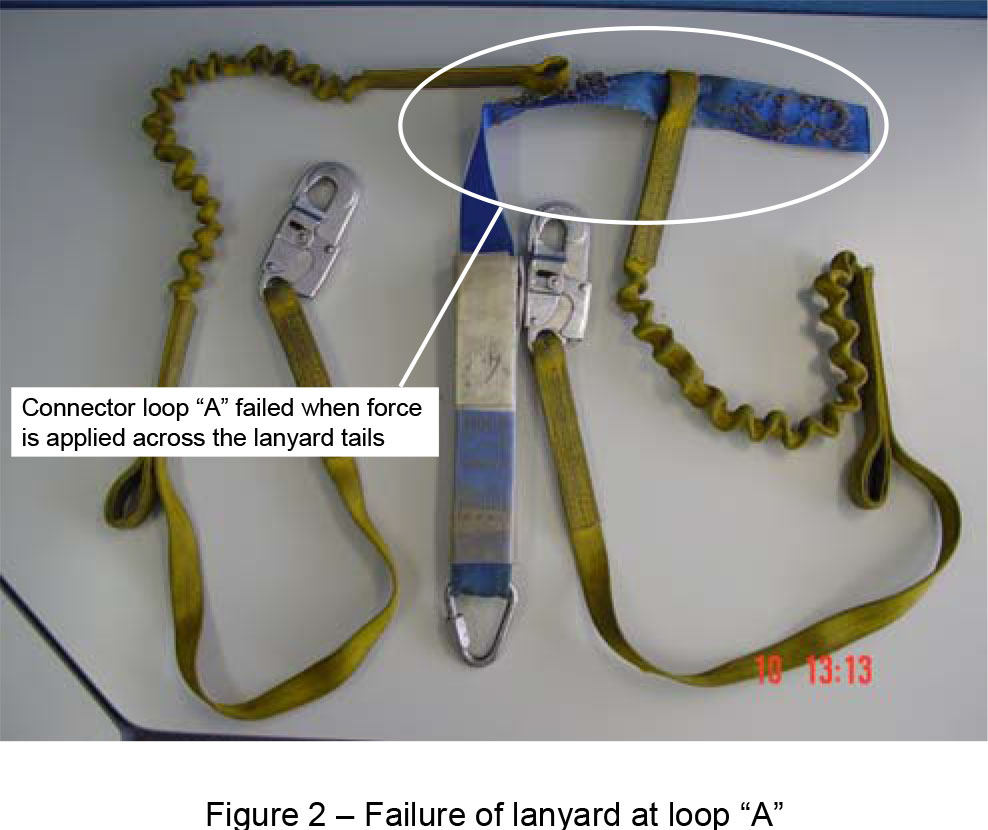

- The lanyard has the potential to fail if a drop test is conducted with one tail of the lanyard anchored and the other connected to the drop weight. The lanyard failed at connector loop “A” (Refer to Figure 2)

From the lanyard used in the incident, it has been observed that the energy absorber on the lanyard did not operate but the webbing on the absorber’s connector loop “A” failed (Refer to Figure 2).

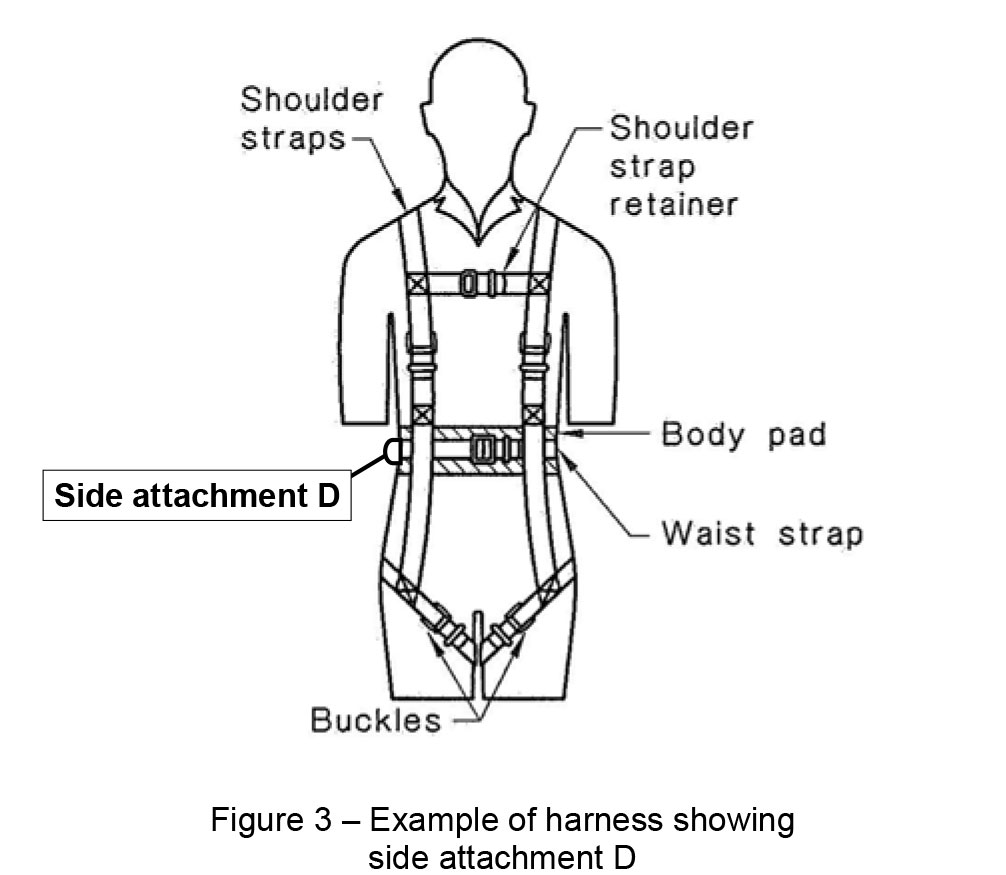

At this stage it is not possible to determine the cause of the incident. However, a number of findings are apparent from the preliminary investigations and the tests conducted on similar lanyards. An important finding that should be highlighted immediately is that failure of the lanyard may occur when one tail of the lanyard is attached to an anchorage point and the other tail is back-hooked in particular configurations to a side attachment D on the harness (Refer to Figure 3).

The side attachment D on the harness is generally intended for the user of the harness to operate in travel restraint/work positioning mode and should not be used for attaching a fall arrest lanyard. Connection of any part of the lanyard to a side attachment D may lead to the energy absorber being by-passed in the event of a fall. The shock loading will effectively be transferred to the twin tails of the lanyard.

Recommendations

In view of the seriousness of the incident and the fact that further investigation needs to take place, WHSQ recommends the following interim measures:

- The use of fall arrest systems are not the preferred method of managing the risks associated with climbing or moving along a structure. Engineering controls, such as the use of elevating work platforms, provide a higher degree of safety. Fall arrest systems should only be used when it is impracticable to use other safer work methods.

- As an interim measure, the use of twin tail fall arrest lanyards should be discouraged from use, pending the outcome of the investigation. However, twin tail fall arrest lanyards may be considered fit for use if users gain an assurance from the manufacturer (based on appropriate test results) that their product will not fail in the event of a fall when one lanyard tail is attached to an anchorage point and the other tail is back-hooked, in any possible configuration, to a side attachment D on the harness. Twin tail fall arrest lanyards that meet this criterion need also to be used in strict accordance with guidelines provided by the manufacturer.

Legislative requirements

Section 28 of the Workplace Health and Safety Act 1995 requires employers to ensure the health and safety of their workers and others at a workplace. Section 31 lists obligations of principal contractors. Section 36 lists obligations of workers and other persons and Section 32 lists obligations of designers, manufacturers, importers and suppliers of plant.

Further information

For more information contact Workplace Health and Safety Queensland

Phone 1300 369 915

Internet www.whs.qld.gov.au